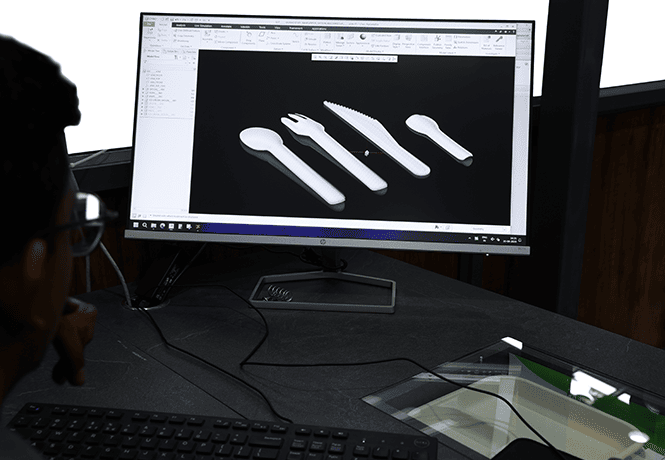

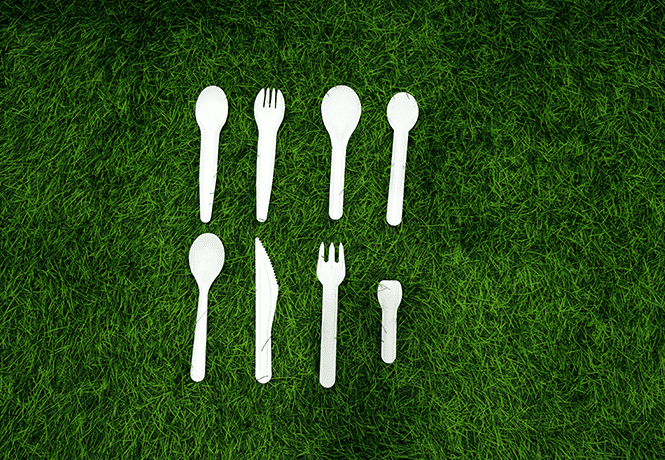

Customer Provides Sample or 3D Drawing Design

The process begins with the customer providing either a physical sample of the paper cutlery or a 3D drawing design of the product they want to manufacture. This sample or design serves as the basis for the mold design.